1. The role and influencing factors of the mixing process

Mixing (melt blending) is the core link of plastic modification. Through mechanical shearing and thermal action, the resin and additives (such as reinforcing fibers, fillers, toughening agents, etc.) are evenly dispersed and a stable microstructure is formed. Its core goals include:

Improving dispersibility (avoiding agglomeration and ensuring uniform distribution of fillers)

Improving compatibility (promoting interface bonding between different components)

Optimizing melt fluidity (affecting subsequent processing and molding)

Key factors affecting the mixing effect

(1) Selection of mixing equipment

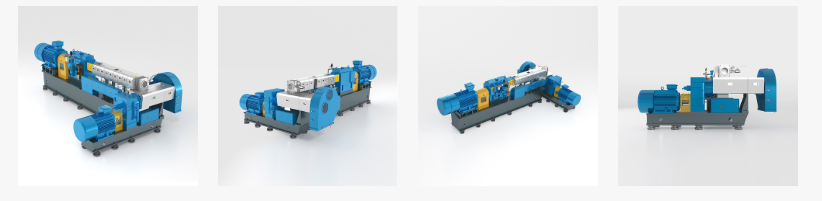

Twin-screw extruder (most commonly used): high shear force, segmented temperature control, suitable for high-filling, high-viscosity systems.

Internal mixer: suitable for high-viscosity materials (such as rubber toughening modification).

Single-screw extruder: low cost, but weak mixing effect, suitable for simple blending.

(2) Process parameter optimization

Temperature control: The melting temperatures of different engineering plastics vary greatly (such as PEEK needs to be above 380°C, PA66 is about 260°C), and segmented heating is required.

Screw speed: High speed increases shear force, but too high speed may cause degradation (e.g. PC is prone to hydrolysis).

Feeding method: Side feeding can be used for the later addition of fibers (e.g. glass fiber) or heat-sensitive additives (e.g. flame retardants).

(3) Material ratio and pretreatment

Matrix resin selection: e.g. PA6+GF reinforcement vs. PC/ABS alloy toughening.

Filler treatment: Nanofillers (e.g. carbon nanotubes) require surface modification to avoid agglomeration.

Compatibilizer addition: e.g. maleic anhydride grafted polymer (PP-g-MAH) can improve the compatibility of non-polar/polar plastics.

2. Common problems and solutions for plastic mixing systems

- Uneven dispersion (filler/additive agglomeration)

Problem manifestation

Fillers (such as calcium carbonate, carbon black) or fibers (such as glass fiber) are unevenly distributed, and "fish eyes" or agglomerated particles appear.

The mechanical properties of the product fluctuate greatly, and color difference or spots appear on the surface.

Possible causes

The filler is not fully dried, resulting in adsorption and agglomeration.

Insufficient mixing shear force (low screw speed or inappropriate temperature).

Improper filler addition method (such as one-time input of a high proportion of filler).

Solution

Pre-treat filler: drying (such as 120℃×4h) or surface modification (silane coupling agent treatment).

Optimize feeding method: use side feeding or segmented addition to avoid instantaneous overload.

Adjust screw combination: add high shear blocks or reverse thread elements to improve dispersion.

- Unstable melt temperature

Problem manifestation

The melt temperature fluctuates greatly, resulting in local degradation of the material or poor plasticization.

Bubbles, black spots or reduced strength appear in the product.

Possible causes

Heating/cooling system failure (such as damaged thermocouple or malfunction of temperature control module).

Screw speed or back pressure fluctuates greatly.

Poor resin fluidity (such as high-viscosity engineering plastic PEEK).

Solution

Calibrate temperature control system: check thermocouples and heating rings regularly.

Optimize process parameters: reduce screw speed or increase barrel temperature (for high melting point plastics).

Increase melt pump: stabilize extrusion pressure and reduce temperature fluctuations.

- Material degradation (yellowing, black spots, strong odor)

Problem manifestation

The melt turns yellow, has black spots, or produces a pungent odor.

Mechanical properties (such as impact strength) are significantly reduced.

Possible causes

Temperature is too high or residence time is too long (such as PC, PVC is easy to decompose).

Screw wear produces metal contamination.

The raw material contains impurities or the proportion of recycled materials is too high.

Solution

Reduce processing temperature: especially heat-sensitive materials (such as PVC, bio-based plastics).

Shorten residence time: increase screw speed or reduce feed rate.

Maintain the equipment regularly: Check the wear of the screw and barrel to avoid metal contamination.

- Fiber breakage (glass fiber/carbon fiber reinforced materials)

Problem manifestation

The fiber length is too short, resulting in a decrease in the reinforcement effect.

The impact resistance and rigidity of the product are insufficient.

Possible causes

The screw shear force is too strong (such as excessive use of meshing blocks).

The fiber is added in an improper position (such as easy to be cut off when added at the main feed port).

Solution

Adding fibers to the side feed: Add in the middle and rear barrel to reduce shear damage.

Optimize the screw design: reduce high shear blocks and increase the proportion of the conveying section.

Select long fiber masterbatch: directly use premixed long fiber reinforcement (such as LFT).

- Excessive volatiles (bubbles, rough surface)

Problem manifestation

There are bubbles in the melt, and the surface of the extruded material strip is not smooth.

The product has voids or warping deformation.

Possible causes

The moisture content of the raw materials is high (such as nylon and PET are easy to absorb moisture).

Small molecule additives (such as lubricants) evaporate.

Solution

Pre-drying raw materials: nylon requires 80℃×4h, PET requires 150℃×4h.

Add exhaust section: use vacuum exhaust extruder to remove volatiles.

Use low-volatile additives: such as high molecular weight silicone instead of small molecule lubricants.

- Screw/barrel wear

Problem manifestation

Mixing efficiency decreases and production capacity decreases.

There are metal chips in the melt and scratches on the product.

Possible reasons

Processing high-filled materials (such as glass fiber, mineral powder) causes wear.

The hardness of the screw material is not enough (such as ordinary 38CrMoAl is not wear-resistant).

Solution

Select wear-resistant screw: double alloy screw or nitriding treatment.

Reduce the filling ratio: optimize the formula and reduce the amount of high-hardness fillers.

Regularly check wear: measure the gap between the screw and the barrel and replace it in time.

Mixing system troubleshooting table:

|

Problems |

Key causes |

Solutions |

|

Uneven dispersion |

Filler agglomeration, insufficient shear |

Pre-treat filler, optimize screw design |

|

Melt temperature fluctuation |

Temperature control failure, unstable back pressure |

Calibrate temperature control system, add melt pump |

|

Material degradation |

Too high temperature, long residence time |

Lower temperature, shorten cycle |

|

Fiber breakage |

Too strong shear force |

Add side feed to reduce high shear blocks |

|

High volatile matter |

Raw materials contain water, additives evaporate |

Pre-drying, increase exhaust |

|

Equipment wear |

High-filling material processing |

Use wear-resistant screws to reduce filling volume |

|

Excessive energy consumption |

Low process/equipment efficiency |

Optimize screws and use energy-saving technology |