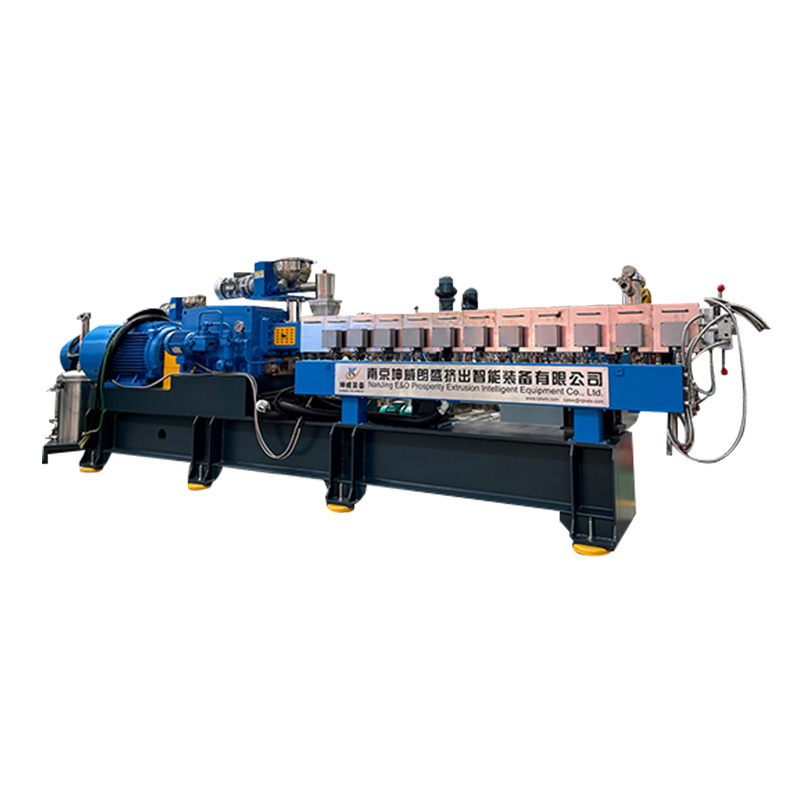

High-speed twin-screw extrusion system is a kind of high-efficiency polymer processing equipment. It realizes material conveying, melting, mixing and extrusion by two intermeshing screws rotating at high speed. Its core functions include high-efficiency plasticization, precise mixing and continuous production. It is widely used in plastics, rubber, food, medicine and other fields.

1. Core functions

(1) High-efficiency melt plasticization

Rapid heating: The high-speed rotation of the screw generates shear heat, which cooperates with the external heater to quickly melt the solid material (such as plastic particles) into a uniform melt.

Adaptable to a variety of materials: It can process thermoplastics (PP, PE, ABS), rubber, biodegradable materials (PLA, PHA), etc.

(2) Precise mixing and dispersion

Distributive mixing: The uniform distribution of fillers (such as glass fiber and calcium carbonate) is achieved through the shear action of the screw meshing zone.

Dispersive mixing: It breaks up agglomerated particles (such as carbon black and nanomaterials) and improves material properties (such as conductivity and mechanical strength).

Reactive extrusion: chemical reactions are completed during the extrusion process (such as grafting modification and polymerization).

(3) Continuous production

The entire process from raw material feeding to finished product extrusion is automated, suitable for large-scale production (such as plastic granulation, sheet, and pipe).

2.Application areas

|

Industries |

Applications |

Technical Advantages |

|

Plastics Processing |

Modified plastics, masterbatches, recycled materials |

High throughput (500-2000 kg/h), low energy consumption |

|

Rubber Industry |

Dynamically vulcanized TPE, rubber blending |

Precise temperature control (±1°C), efficient vulcanizing agent dispersion |

|

Food and Pharmaceuticals |

Plant protein extrusion, sustained-release drug carriers |

FDA/GMP compliant, pollution-free |

|

New Energy |

Lithium battery separators, conductive polymer materials |

Uniform dispersion of nanomaterials |

3. Maintenance considerations for high-speed twin-screw extrusion systems

Daily Maintenance (per 8-hour shift)

Lubrication system inspection

Gearbox oil level monitoring (centerline position of the oil window)

Confirm that all lubrication points (such as bearing seats) are not abnormally hot (temperature < 65°C)

Operating parameter recording

Compare current/torque fluctuations (abnormal fluctuations within ±10% require investigation)

Record melt pressure (normal range 5-30 MPa)

Quick cleaning

Remove residual material from the feed port (to prevent bridging)

Clean carbon deposits from the die outlet with a copper brush

Deep maintenance of key components

Screw assembly maintenance

Ultrasonic cleaning after disassembly (do not use wire brushes)

Inspect thread wear (heavy Monitoring the melting section)

Surface hardness test (HRC ≥ 58 is acceptable)

Barrel maintenance

Inner wall roughness test (Ra ≤ 0.8μm)

Nitride layer thickness measurement (≥ 0.3mm)

Drive system

Gearbox bearing clearance adjustment (axial ≤ 0.05mm)

Coupling alignment (deviation < 0.02mm)

Shutdown maintenance procedures

Short-term shutdown (< 72 hours)

Flush the screw with pure HDPE (to prevent corrosion)

Set the die head temperature to 80-100°C

Long-term shutdown (> 7 days)

Disassemble the screw and apply anti-rust oil (food-grade grease)

Drain the gearbox lubricant

Dehumidify the control cabinet (humidity < 60% RH)