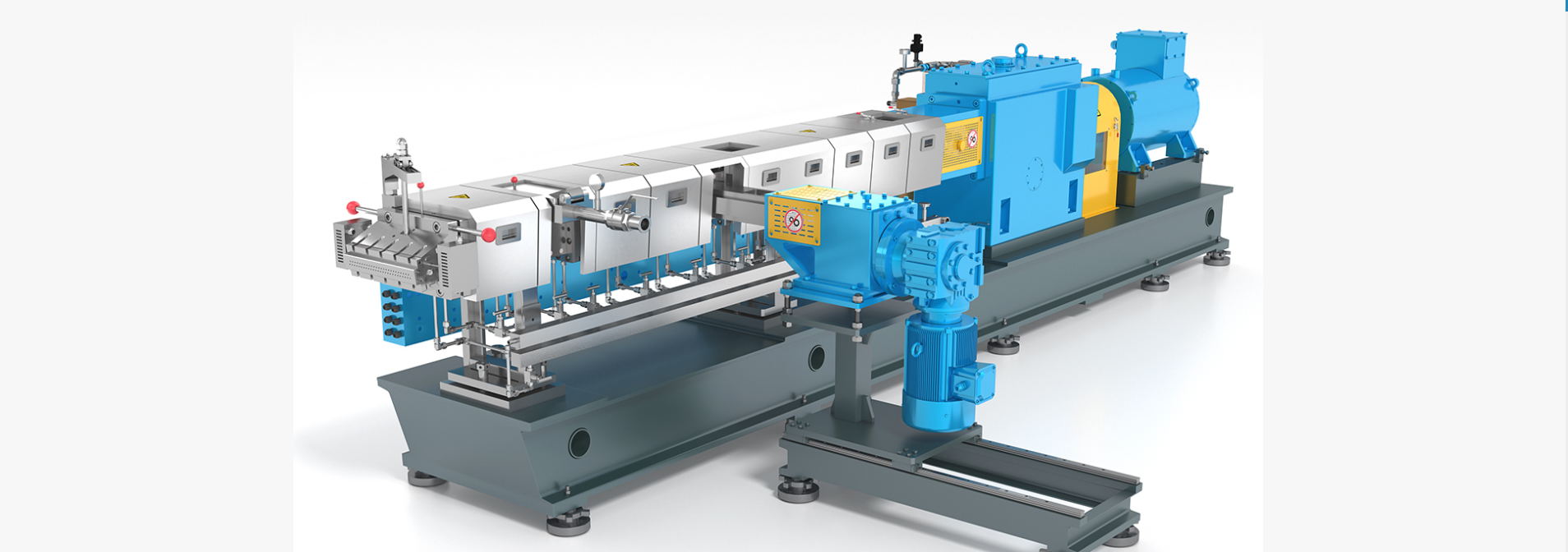

The KTD high-volume extruder is a large-scale machine used for processing polymer materials, primarily for continuous extrusion processes in the plastics, rubber, and chemical industries. Its core function is to melt, mix, and extrude solid raw materials (such as plastic granules and powder) through high temperature, high pressure, and mechanical shear, ultimately producing a product or semi-finished product with a specific shape.

1. Functions of the KTD high-volume extruder

Efficient Melt Extrusion: The large-volume design is suitable for large-scale production, enabling rapid melting and homogenization of raw materials, and then extrusion through the screw.

Mixing and Plasticizing: The shearing and mixing action of the screw ensures thorough mixing of raw materials (such as plastics, fillers, and additives), improving material uniformity.

Continuous Production: Supports long-term continuous operation, suitable for industrial large-scale manufacturing, and reduces unit costs.

2. Applications

Plastic Products: Production of pipes, plates, profiles (such as door and window profiles), sheets, films, etc.

Cable Jacketing: Extrusion of insulating or protective layers for cables.

Rubber Processing: Used for extrusion molding of rubber products such as tires and weatherstrips.

Recycling: Processing waste plastics, re-pelletizing them through melt extrusion or direct molding.

3. Advantages Compared to Conventional Extruders

Productivity Advantage: Suitable for large-volume orders, reducing the number of equipment required. Stability: Heavy-duty structural design reduces vibration and ensures long-term operational stability.

Automation Integration: Automatic feeding, online detection, and other systems are often included to improve efficiency.

4. Precautions for using KTD large-capacity extruder

(1) Preparation before operation

Equipment inspection

Confirm that key components such as the screw, barrel, and die head are free of wear or residue to avoid blockage or scratches.

Check whether the heating/cooling system, lubrication system, and electrical control are normal.

Tighten all connecting bolts (such as flanges and die heads) to prevent loosening and leakage under high pressure.

Raw material processing

Raw materials must be dry (especially hygroscopic materials such as PET and nylon) to avoid moisture causing bubbles or degradation.

Screen out impurities (such as metal particles) to prevent damage to the screw or barrel.

Temperature preheating

Start the heating system in advance, heat up to the process temperature in stages and keep warm (to avoid local overheating).

Forbidden to start at low temperature to avoid excessive torque damaging the screw or motor.

(2) Key control during operation

Temperature management

Monitor the temperature of each section (barrel, die head). Excessive temperature difference can easily lead to uneven melt or degradation. The cooling system needs to be adjusted to prevent overheating (such as PVC is easy to decompose) or insufficient cooling (such as PE adhesion). Screw speed and feeding Low speed start: gradually increase the speed to the set value to avoid instantaneous high load. Balanced feeding: keep the hopper unloading continuously to prevent material interruption and screw idling wear. Load monitoring: when the current or torque increases abnormally, check immediately (possibly blockage or poor plasticization). Pressure control When the melt pressure is too high (such as die blockage), it is necessary to stop the machine for cleaning and do not force pressure. Check the accuracy of the pressure sensor regularly.

(3) Safety and maintenance points Personal safety Wear protective equipment (gloves, goggles) to prevent burns when handling high-temperature melt or cleaning. Cut off the power supply and hang a warning sign when stopping for maintenance to prevent accidental start-up. Daily maintenance Cleaning: clean the die head and screw residue after each shutdown (especially corrosive materials such as PVC). Lubrication: regularly add reducer and bearing grease (according to the manufacturer's cycle). Wear inspection: Regularly measure the clearance between the screw and the barrel. Replace the screw if the wear exceeds the standard.

Long-term outage

Empty the material in the machine to avoid residual carbonization.

Apply anti-rust oil to protect the screw and the inner wall of the barrel.

(4) Troubleshooting

Unstable discharge: Check for temperature fluctuations, screw wear or uneven feeding.

Abnormal noise: Possible bearing damage, screw deformation or foreign matter stuck.

Finished product defects (such as bubbles, streaks): Adjust the temperature, clean the die head or replace the filter.