A hot-melt extruder (HME) is an industrial device that melts, mixes, and homogenizes materials (typically a mixture of polymers and active ingredients or other additives) under the influence of heat and mechanical shear, ultimately extruding them continuously through a die of a specific shape.

A hot-melt extruder is essentially a continuous "melt mixer." Its core principle is to plasticize the material using thermal energy (external heating) and mechanical energy (shear force and frictional heat generated by the rotation of the screw) and then, with the help of the screw's thrust, push it through the die, forming the desired shape.

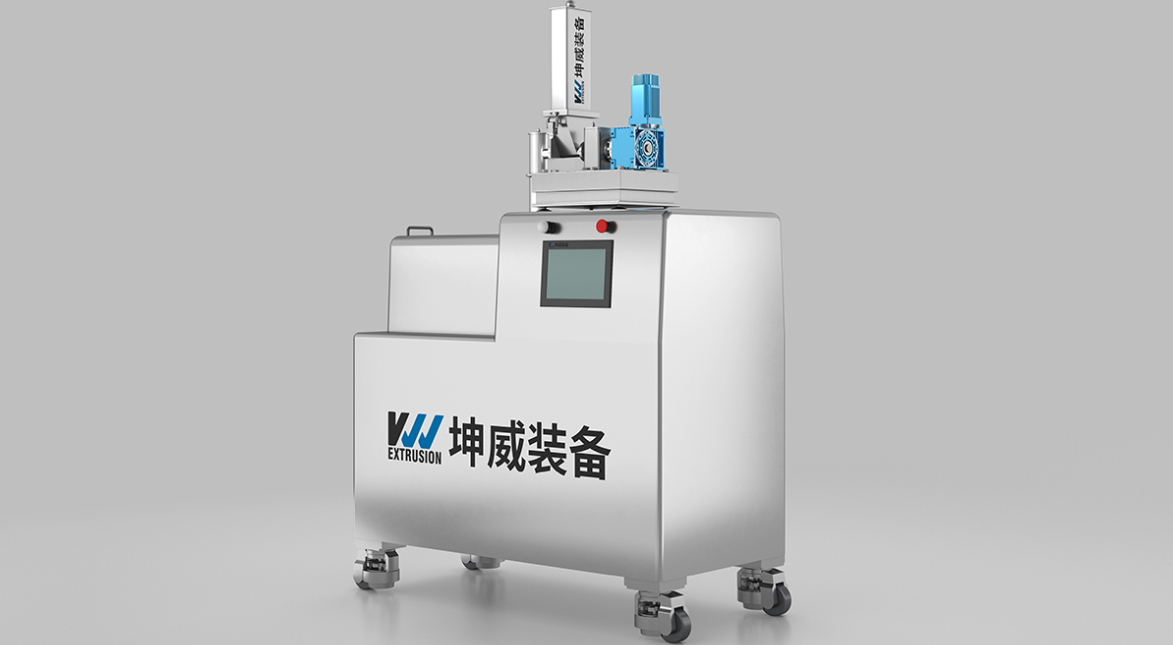

1. Main Components of a Hot-Melt Extruder

A typical hot-melt extruder (taking the most commonly used screw type as an example) typically consists of the following key components:

Feeding System: Typically a hopper that stores and continuously and steadily feeds the raw material (powder, granules, or liquid) into the barrel.

Barrel: A rigid metal cylinder that houses the screw. The barrel is divided into multiple heating zones, each of which can be independently and precisely temperature-controlled to gradually heat the material.

The screw is the heart of the extruder. It is a rotating shaft with a special thread structure. Its main functions are:

Conveying: It pushes the material from the feed end to the die end.

Compression: Reducing the screw groove depth or changing the pitch compresses the material and expel air.

Shearing and mixing: The rotating screw exerts strong shear forces on the material, causing it to melt thoroughly and mix evenly.

Heating and cooling systems: They provide precise temperature control to ensure that the material is processed at the optimal temperature and prevent degradation due to overheating.

Die: Installed at the end of the extruder, it determines the final shape and size of the extruded product (such as filament, ribbon, or tube).

Drive system: It provides rotational power to the screw and controls its speed, thereby affecting the material's residence time and shear intensity.

Control system: Modern extruders are controlled by computer systems that can precisely set and monitor all key process parameters, including temperature, screw speed, and feed rate.

2. Main Types of Hot Melt Extruders

Based on the number and structure of screws, they are primarily categorized as follows:

Single-screw extruders: These have a relatively simple structure and rely primarily on drag flow to transport materials, resulting in weak mixing capabilities. They are more suitable for pre-mixed materials or applications where mixing uniformity is less critical.

Twin-screw extruders: These are currently the most widely used and most efficient type. Two intermeshing screws rotate within the barrel, generating not only drag flow but also strong shear and convection currents, resulting in excellent mixing. Based on the direction of the screws, they are categorized as either co-rotating or counter-rotating. Co-rotating twin-screw extruders, due to their superior self-cleaning properties and mixing efficiency, have become the absolute mainstream in fields such as pharmaceuticals and polymer alloys.

3. Product Advantages of Hot Melt Extruders

Hot melt extrusion technology, particularly in the pharmaceutical and high-end material sectors, offers the following advantages over traditional processes (such as wet granulation):

Solvent-free/Environmentally Friendly: The entire process generally does not require the use of any organic solvents, eliminating the problems of solvent residue, recycling, and environmental pollution, making it a "green" manufacturing process. Continuous production: Enables 24/7 uninterrupted production, resulting in high production efficiency, large batch sizes, minimal batch-to-batch variability, and more consistent quality.

Improving the solubility of poorly soluble drugs: This is its greatest value in the pharmaceutical field. By forming a solid dispersion, the drug molecules are highly dispersed in a polymer carrier, significantly improving the dissolution rate and bioavailability of poorly soluble drugs.

Versatility: In addition to improving dissolution, it can also be used for taste masking, preparing sustained-release formulations, and manufacturing transdermal drug delivery systems and implants.

High energy input: Strong shear forces effectively disperse nanoparticles or other functional fillers, creating new materials with unique properties.