What is the impact of the hopper design of the screw extruder feeding system on the feeding efficiency?

The hopper's diameter and volume directly affect the feeding speed. If the hopper mouth is too small or the volume is insufficient, the material supply will be poor, affecting the feeding efficiency. On the contrary, a reasonable hopper size can ensure that the material enters the screw extruder stably and quickly. The shape design of the hopper should take into account the fluidity and stacking characteristics of the material. For example, the use of rounded corners can reduce the wall hanging phenomenon of the material in the hopper and improve the fluidity of the material. At the same time, a reasonable hopper shape can also prevent the material from agglomerating or clogging during the feeding process.

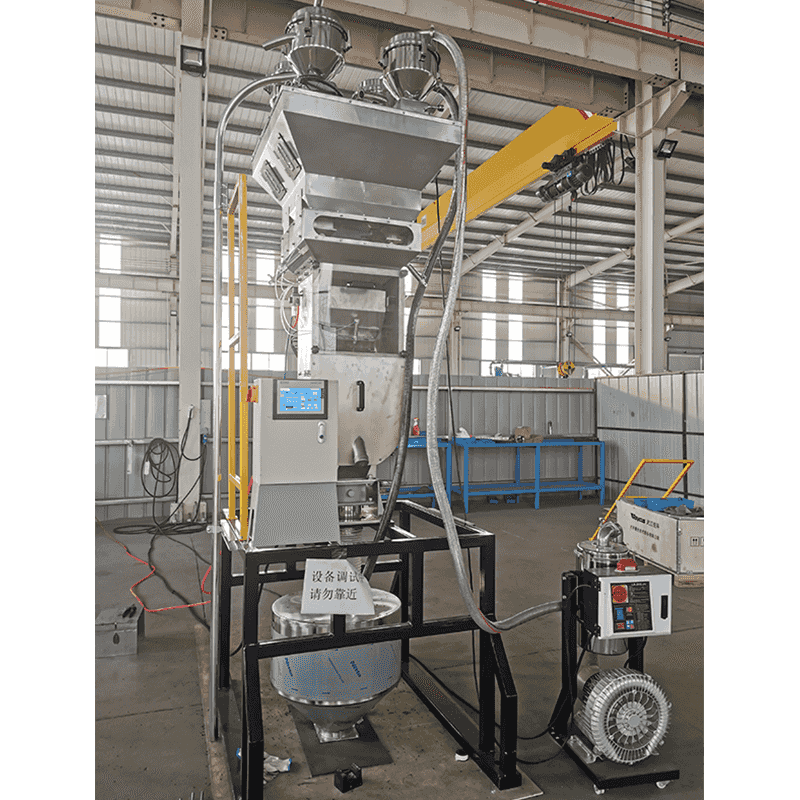

Some hoppers will have grids or partitions inside. These structures can separate the material into different levels or areas, which helps to improve the fluidity and uniformity of the material. For example, the grid can reduce the unit volume of the material, avoid the material from agglomerating and arching, and thus improve the feeding efficiency. In order to further improve the feeding efficiency, some hoppers will also be equipped with a vibration device. The vibration device can vibrate the hopper regularly or continuously to help loosen the material, eliminate blockages, and ensure that the material enters the screw extruder smoothly.

The distance between the hopper and the die is also a data that needs to be controlled. If the distance is too large, the resistance and time of the material in the feeding process will increase, resulting in a slower feeding speed. Therefore, the reasonable adjustment of the distance between the hopper and the die can reduce the resistance of the material in the feeding process and improve the feeding efficiency.

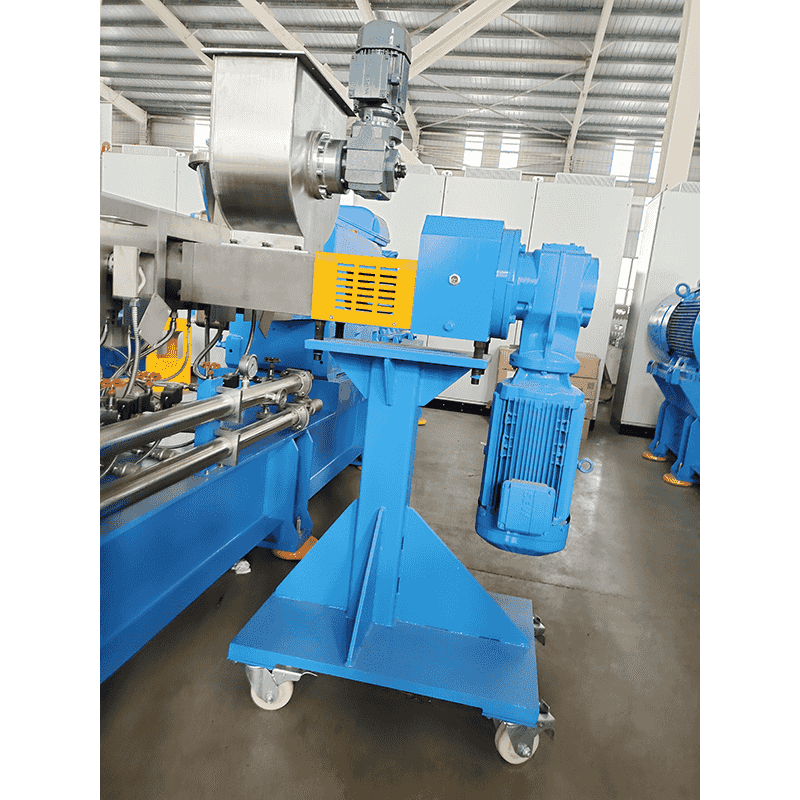

Optimizing the hopper design can significantly increase the feeding speed of the screw extruder. Through reasonable size, shape and internal structure design, as well as appropriate vibration device and spacing adjustment, it can ensure that the material enters the screw extruder stably and quickly. Unreasonable hopper design is prone to cause material blockage, leakage and other failures. By optimizing the hopper design, the incidence of these failures can be reduced and the stability and reliability of the screw extruder can be improved. The improvement of feeding efficiency is directly related to the production efficiency of the entire production line. Optimizing the hopper design can reduce downtime and increase production speed, thereby creating greater economic benefits for the enterprise.

The hopper design of the screw extruder feeding system can significantly improve the feeding speed and production efficiency, reduce the failure rate, and create greater economic benefits for the enterprise through reasonable size, shape and internal structure design, as well as appropriate vibration device and spacing adjustment. In practical applications, the appropriate hopper design should be selected based on specific production requirements and material characteristics.