High-torque twin-screw extruders are powerful machines used in various industries for processing polymers and other materials. These machines are know...

READ MOREWeb Menu

Product Search

Exit Menu

Screw Extruder Mixing System Company

Advanced structure, high-quality performance, easy to use, high reliability and durability.

Screw Extruder Mixing System Supplier

-

The formula material can be pre-mixed to a certain extent before being added to the twin-screw extru...

More

From consulting during process and production optimization, installation, system set-up and start-up right through to the verification of the specific product quality.

- System planning

- System logistics

- Basic design of building and infrastructure

- Interface coordination with third parties

- Project development

- Training, production support and servicing

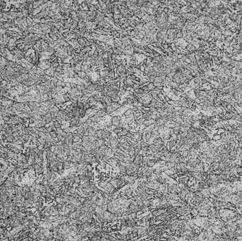

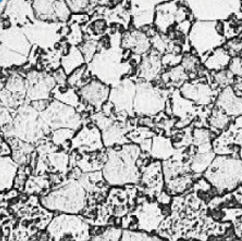

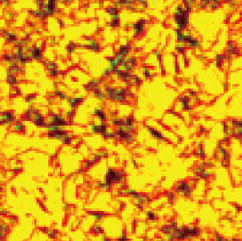

We offer wide range of Moc for barrels, screw elements and shafts.

With our exclusively developed extremely wear and corrosion resistant material, the service life of barrels could be extended several times compared to HIP material for compounding polymers with glass and carbon fibers, ceramic and metal masses, and inorganic fillers.

- Nitrided Steel

- Special Stainless Steel

- SAM26/WR13

- Hastelloy

- Nickel-based WC

- Cobalt-based WC

The unique intelligent control system can realize a variety of customized functions for you, realize intelligence and dataization, and improve operating efficiency and production stability.

- Mega data storage and analysis

- Compatible with all industrial bus protocol

- Machine-learn algorithm to predict malfuncton and optimize parameters

-

-

Improving production efficiency is a key goal for manufacturers using an Engineering Plastic Extrusion Production Line. Higher efficiency not only red...

READ MORE -

The pharmaceutical hot melt extruder (Hot Melt Extruder, HME) is a crucial piece of equipment in the modern pharmaceutical industry. It primarily util...

READ MORE -

In the production process of chemical products, improving product quality and production efficiency is a crucial issue for every enterprise. With the ...

READ MORE

What special designs are there for the screw extruder mixing system when dealing with highly abrasive or corrosive materials?

When the screw extruder is dealing with highly abrasive or corrosive materials, its mixing system will adopt special designs to ensure the stable operation of the equipment and extend its service life. For the selection of materials, the screw and barrel are usually made of high-strength, high-wear-resistant and high-temperature-resistant alloy steel materials, which can withstand high temperature and high pressure environments and resist material wear. For particularly high-abrasive or corrosive materials, the surface of the screw and barrel may be treated with special coatings, such as nitriding, chrome plating or spraying of wear-resistant and corrosion-resistant materials to improve their wear resistance and corrosion resistance. For corrosive materials, the lining of the extruder may use materials with better corrosion resistance, such as stainless steel, ceramics or special alloys, to reduce the corrosion of the material to the equipment.

In the structural design of the screw extruder mixing system, the screw adopts a modular design, so that the screw can be quickly replaced or adjusted according to different production needs to meet the processing requirements of different materials. This design is also convenient for repairing and replacing severely worn parts. By optimizing the screw geometry, such as pitch, groove depth and thread shape, the mixing effect of the material can be improved and the wear of the screw can be reduced. The barrel adopts a split design, so that the barrel can be opened for easy cleaning and maintenance. This design is particularly suitable for processing materials that are easy to agglomerate or corrosive, and it is convenient to remove the material remaining in the barrel in time.

In the screw extruder mixing system, modern screw extruders often use automatic control systems. These systems can monitor the production process in real time and automatically adjust operating parameters such as temperature, pressure and speed to ensure the consistency and stability of product quality. At the same time, automatic control also helps to reduce the damage to the equipment caused by human operating errors. For materials that require high temperature processing, the extruder will be equipped with a precise temperature control system to ensure that the temperature of the barrel and screw is always kept within the appropriate range to avoid excessive temperature causing material decomposition or equipment damage.

For extruders running at high temperatures, a cooling system may be equipped to reduce the temperature of the equipment and reduce the damage to the equipment caused by thermal stress. A good lubrication system can reduce the friction and wear between the screw and the barrel. For high-wear materials, special lubricants or lubrication methods may be required. An efficient sealing system can prevent corrosive materials from leaking outside the equipment, protecting the safety of the equipment and the production environment.

When dealing with highly abrasive or corrosive materials, the screw extruder uses special designs in material selection, structural design, control systems and other auxiliary measures to ensure stable operation and extend the service life of the equipment. These designs not only improve the adaptability and flexibility of the equipment, but also reduce production costs and maintenance difficulties.

Bringing Craftsmanship to the Future.

No. 11, Zijin Road, Dujiangyan Economic Development Zone, Chengdu City, Sichuan, China