High-torque twin-screw extruders are powerful machines used in various industries for processing polymers and other materials. These machines are know...

READ MOREWeb Menu

Product Search

Exit Menu

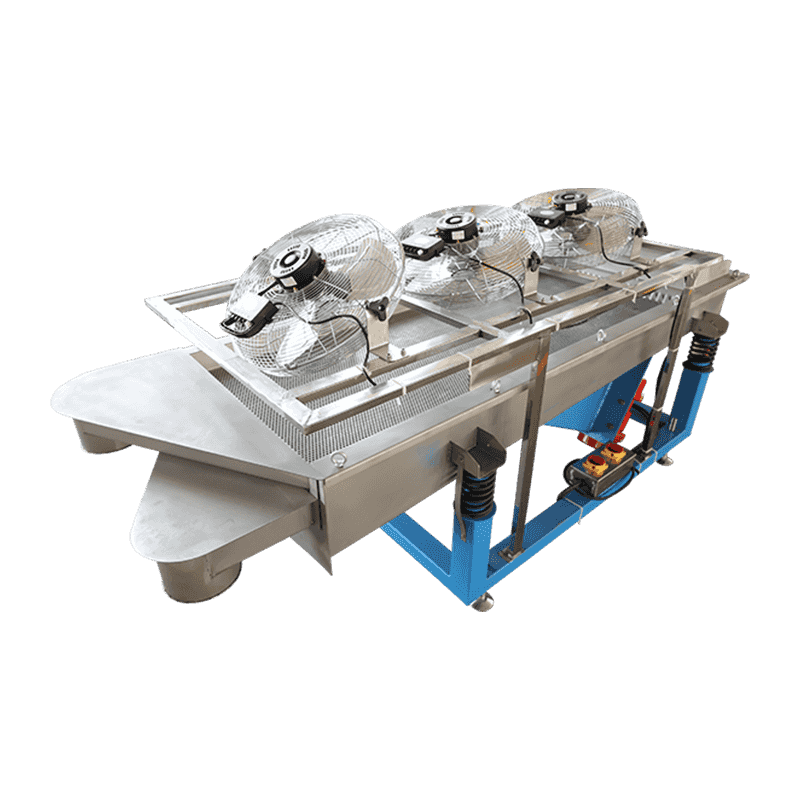

Screw Extruder Sieving-Storage System Factory

Advanced structure, high-quality performance, easy to use, high reliability and durability.

From consulting during process and production optimization, installation, system set-up and start-up right through to the verification of the specific product quality.

- System planning

- System logistics

- Basic design of building and infrastructure

- Interface coordination with third parties

- Project development

- Training, production support and servicing

We offer wide range of Moc for barrels, screw elements and shafts.

With our exclusively developed extremely wear and corrosion resistant material, the service life of barrels could be extended several times compared to HIP material for compounding polymers with glass and carbon fibers, ceramic and metal masses, and inorganic fillers.

- Nitrided Steel

- Special Stainless Steel

- SAM26/WR13

- Hastelloy

- Nickel-based WC

- Cobalt-based WC

The unique intelligent control system can realize a variety of customized functions for you, realize intelligence and dataization, and improve operating efficiency and production stability.

- Mega data storage and analysis

- Compatible with all industrial bus protocol

- Machine-learn algorithm to predict malfuncton and optimize parameters

-

-

Improving production efficiency is a key goal for manufacturers using an Engineering Plastic Extrusion Production Line. Higher efficiency not only red...

READ MORE -

The pharmaceutical hot melt extruder (Hot Melt Extruder, HME) is a crucial piece of equipment in the modern pharmaceutical industry. It primarily util...

READ MORE -

In the production process of chemical products, improving product quality and production efficiency is a crucial issue for every enterprise. With the ...

READ MORE

What is the main function of the screw extruder sieving-storage system?

Screening and grading: Screening is a key link in the subsequent processing of the screw extruder, and it is not just to remove impurities. Through the high-precision screen design, the system can carefully separate particles of different particle sizes in the material and achieve accurate grading. This grading not only helps to improve the final quality of the product, such as improving surface finish and enhancing physical properties, but also provides more suitable raw materials for downstream processes.

Homogenization: Homogenization can ensure that the components in the material are evenly distributed, reduce component deviations, and improve the overall quality of the product. This process involves efficient stirring devices and mixing technologies that can quickly and evenly mix materials and eliminate local concentration differences. For materials that require precise proportions, such as masterbatches and functional additives, homogenization is particularly important, which is directly related to the final performance and appearance of the product.

Drying and cooling: Some materials may contain high moisture or temperature during the extrusion process, which is not conducive to subsequent storage and processing. Therefore, the screening and storage system is usually equipped with drying and cooling equipment. Drying equipment removes excess moisture from the material by heating and ventilation, while cooling equipment is used to reduce the temperature of the material to achieve suitable storage conditions.

Storage and protection: Another important function of the screening and storage system is to provide a safe and stable storage environment to protect the material from external environmental factors. The system uses containers or packaging bags with good sealing performance to prevent air, moisture and impurities from entering, thereby maintaining the cleanliness and quality stability of the material. At the same time, the system may also have temperature control and humidity adjustment functions to maintain the stability of the material under optimal storage conditions.

Automation and efficiency improvement: Modern screw extruder sieving-storage systems have achieved a high degree of automation and intelligence. By integrating advanced control systems and sensor technology, the system can monitor various parameters in the production process in real time, such as temperature, humidity, particle size distribution, etc., and automatically adjust the equipment operation status according to preset process requirements. This automation and intelligence not only improves production efficiency, reduces the cost and risk of manual intervention, but also improves the stability and consistency of product quality. At the same time, the system also has data recording and analysis functions, which provides strong support for the company's quality management and continuous improvement.

The main function of the screw extruder sieving-storage system is to refine the materials produced by the extruder through screening, homogenization, drying, cooling and storage processes, improve the quality and stability of the products, and realize the automation and efficiency improvement of the production process.

Bringing Craftsmanship to the Future.

No. 11, Zijin Road, Dujiangyan Economic Development Zone, Chengdu City, Sichuan, China