Plastics, as a widely used material in industry, are extensively used in automotive, construction, electronics, and medical fields due to their advantages such as lightweight, corrosion resistance, and ease of processing. However, many plastics have limited performance in certain applications, such as strength, heat resistance, and abrasion resistance. Therefore, how to improve the performance of plastics through technical means to meet different application requirements has become an important issue in the plastics industry. A plastic compounding and modification system is an effective tool for solving this problem, modifying the structure and properties of plastics through physical or chemical means to improve their overall performance.

1. What is a plastic compounding and modification system?

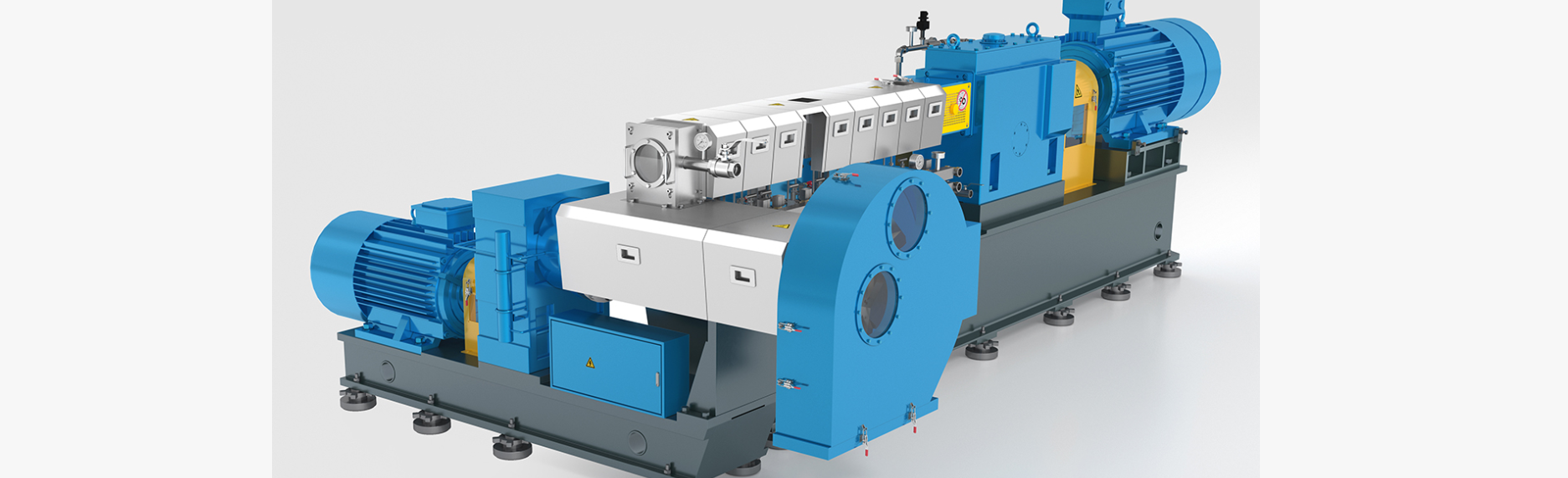

A plastic compounding and modification system is a production equipment and system that uses different types of raw materials (such as plastic base materials, additives, fillers, plasticizers, stabilizers, etc.) through processes such as mixing, heating, and extrusion to obtain modified plastics. The core objective of this process is to modify the molecular structure of the plastic to make its performance superior and adaptable to more complex application environments.

2. How do plastic compounding modification systems improve plastic performance?

(1) Enhancing Mechanical Properties

The mechanical properties of plastics are important indicators of their application value, including strength, hardness, rigidity, and toughness. Many pure plastics, while possessing good processing properties, often exhibit insufficient mechanical properties in practical applications, failing to meet the needs of specific scenarios.

By using plastic compounding modification systems, reinforcing materials such as glass fiber and carbon fiber are added to the plastic matrix, significantly improving the strength and rigidity of the plastic. Especially in fields such as automobile manufacturing and building materials, where the strength requirements for plastics are very high, the overall performance of plastic products is improved after adopting compounding modification technology.

(2) Improving Thermal Stability

Thermal stability is the ability of plastics to be used long-term under high-temperature conditions. Many traditional plastic materials are prone to deformation, aging, or decomposition at high temperatures, thus limiting their application in high-temperature environments. Plastic compounding modification systems can effectively improve the thermal stability of plastics by adding heat stabilizers, antioxidants, and other chemical substances. For example, plastics such as polycarbonate (PC) and polyamide (PA), after modification, can maintain their physical properties at higher temperatures, thus finding wide application in demanding high-temperature fields such as automotive engine parts and electronic and electrical components.

(3) Improved Abrasion Resistance and Corrosion Resistance

The abrasion resistance and corrosion resistance of plastics are key indicators for evaluating their service life in mechanical parts and industrial equipment. In some applications, plastics need to withstand high-frequency friction or contact with chemicals; without sufficient abrasion resistance and corrosion resistance, plastic products are prone to premature damage.

Through plastic compounding modification systems, various fillers, such as ceramics, glass fibers, and graphite, can be added to plastics. These additives can effectively improve the hardness, abrasion resistance, and corrosion resistance of plastics. For example, reinforced polyethylene (PE) or polypropylene (PP) materials perform particularly well in high-intensity working environments such as machining and conveying equipment.

(4) Improved Processing Performance

Plastics often face problems such as poor flowability, uneven temperature, and bubble formation during processing, especially in injection molding or extrusion molding of complex shapes. These problems can affect product quality and production efficiency. Plastic compounding modification systems can improve the flowability and processing performance of plastics by adding appropriate plasticizers and flowability improvers, thereby reducing the defect rate in production.

For example, before modification, polyvinyl chloride (PVC) may have a high melt viscosity during processing, leading to molding difficulties; however, plastic compounding modification can improve its flowability, making it easier to process and mold, suitable for products such as films and pipes.

(5) Improving Transparency and Gloss

Transparent plastics play an important role in many applications, especially in packaging and electronic displays. However, many plastic materials often exhibit opacity or rough surfaces during production, affecting their aesthetics and performance. Compounding modification can improve the transparency and gloss of plastics, making them more in line with market demands in terms of appearance and quality.

(6) Improving Flame Retardancy

Flame retardancy is a key indicator for plastics in many applications with high safety requirements. Plastic compounding modification systems can significantly improve the flame retardancy of plastics by adding flame retardants and refractory materials, reducing their flammability and spread in a fire. For example, modified polypropylene (PP) materials can be widely used in the electronics, electrical, and construction industries, providing higher safety and fire resistance, ensuring application in high-risk environments.

3. Application Areas of Plastic Compounding and Modification Systems

Plastic compounding and modification technology is widely used in the following industries:

(1) Automotive Industry: To improve the strength, high-temperature resistance, and corrosion resistance of automotive parts, plastic compounding and modification technology is widely used in multiple areas such as car bodies, engine parts, and interior parts.

(2) Construction Industry: Modified plastics are widely used in building materials, especially high-temperature resistant and corrosion-resistant plastics for pipes, doors, windows, floors, and other building facilities.

(3) Electronics Industry: Modified plastics can be used in the manufacture of electronic components, improving their heat resistance, electrical properties, and antistatic properties.

(4) Packaging Industry: Modified plastics improve the transparency and abrasion resistance of plastics, making them more promising for application in the packaging industry.

Plastic compounding and modification systems can improve the overall performance of plastics through the scientific formulation and optimization of raw materials, thereby meeting the high performance requirements of various industrial sectors. With continuous technological development and innovation, plastic compounding and modification systems will play a key role in more application areas, driving the plastics industry towards a more efficient, environmentally friendly, and sustainable direction.