In the production process of chemical products, improving product quality and production efficiency is a crucial issue for every enterprise. With the continuous development of technology, high-speed twin-screw extrusion systems have become one of the key technologies for improving product quality and production efficiency in the chemical industry. Twin-screw extruders, with their superior mixing, plasticizing, reaction, and conveying capabilities, are widely used in various fields such as plastics, rubber, pharmaceuticals, and food, and demonstrate unique advantages, especially in complex processes, precise control, and high-efficiency production.

1. Basic Principles and Structure of High-Speed Twin-Screw Extrusion Systems

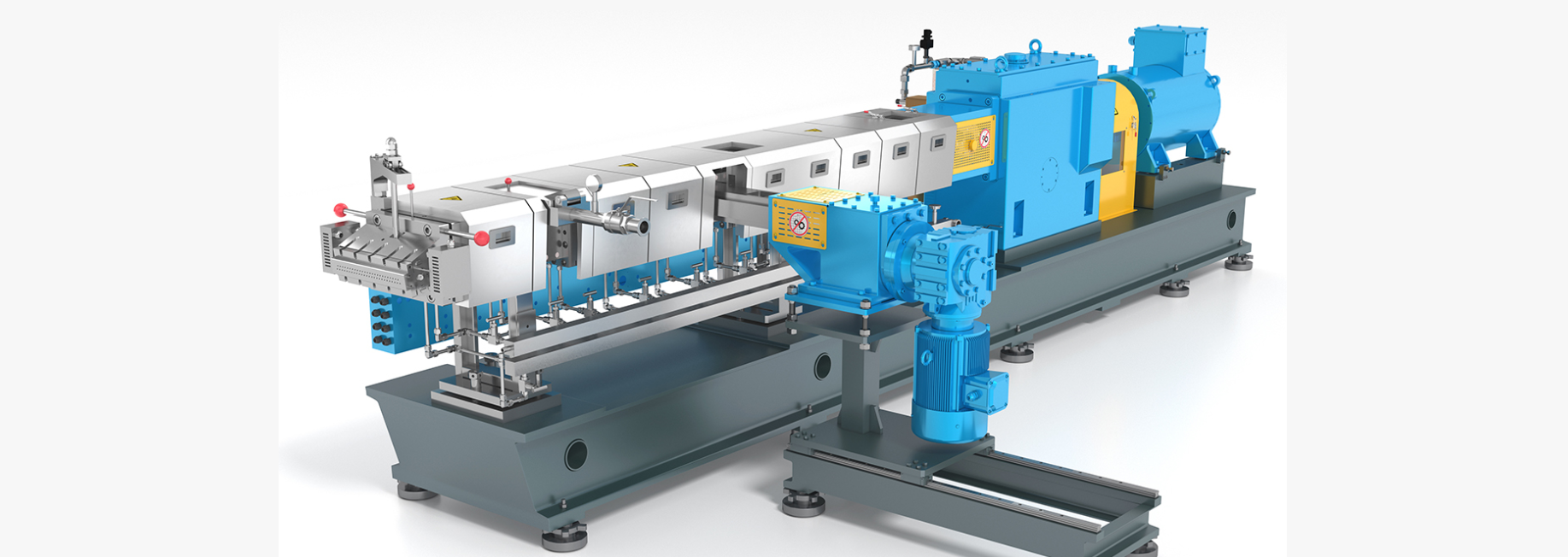

A high-speed twin-screw extruder consists of two intermeshing, synchronously rotating screws, usually operating in a parallel or intermeshing manner. After the material enters the extruder, the twin screws, through the shear force, friction, and pressure generated by rotation, heat, mix, plasticize, react, and extrude the material. Compared with traditional single-screw extruders, twin-screw extruders are more efficient in processing high-viscosity and reactive materials and offer better controllability.

2. Advantages in Improving the Quality of Chemical Products

(1) Precise Mixing and Plasticizing Capabilities

High-speed twin-screw extrusion systems can thoroughly mix different materials in a short time. By optimizing the screw design and rotation speed, the uniformity and stability of the materials can be ensured, avoiding the uneven mixing common in single-screw extruders. This is crucial for chemical products that require strict formula control, especially those with multiple additives or special functional requirements.

(2) Improved Molecular Structure Consistency

In the production process of some chemical products, controlling the molecular structure is particularly important. For example, the molecular chain structure of plastics and rubber directly affects the mechanical properties, thermal stability, and other characteristics of the product. Twin-screw extruders, through precise temperature and pressure control, can effectively adjust the length and cross-linking degree of the molecular chains, thereby ensuring the consistency and stability of the final product quality.

(3) Enhanced Thermal Stability and Performance

Many chemical raw materials are extremely sensitive to temperature during the production process; excessively high temperatures can lead to degradation or loss of original properties. The high-speed twin-screw extrusion system features a powerful temperature control system, allowing for precise temperature control during the heating process, preventing material overheating and degradation, and ensuring high product quality. This is particularly crucial in the production of pharmaceuticals and high-end chemical products.

(4) Realization of Modification and Value-Added Functions

The high shear force and strong mixing capabilities of the high-speed twin-screw extruder make it excellent in chemical modification and the preparation of functional additives. By introducing different reactor configurations, the twin-screw extruder can achieve chemical reactions such as cross-linking, grafting, and polymerization during the material extrusion process, improving product performance. For example, in the modification of plastics, the twin-screw extruder can effectively improve the heat resistance and mechanical strength of the material.

3. Ways to Improve Production Efficiency

(1) High-Speed Operation and High Production Capacity

One of the main advantages of the high-speed twin-screw extruder is its high rotational speed and large production capacity. Under the same production conditions, the twin-screw extruder can process more materials than traditional equipment, significantly improving production efficiency. This is of great importance for large-scale production and increasing enterprise capacity, especially in situations where market demand fluctuates significantly. The high-speed twin-screw extruder can quickly respond to production needs and ensure production stability.

(2) Continuous Production and Reduced Downtime

Unlike traditional batch production methods, the twin-screw extrusion system uses a continuous production mode, allowing for efficient operation without interruption. This not only improves production efficiency and reduces downtime but also reduces manual intervention and minimizes production instability caused by operational errors.

(3) Energy Saving and Cost Control

The high-speed twin-screw extruder effectively saves energy consumption through efficient heat transfer and mixing processes. This is particularly important, especially in long-term large-scale production, where reduced energy consumption directly impacts the company's cost structure. In addition, reducing the scrap rate is also one of the key factors in improving production efficiency. Through precise material proportioning and efficient extrusion processes, companies can reduce the scrap rate, thereby further reducing production costs.

(4) Flexible Adaptation to Various Materials and Processes

The high-speed twin-screw extruder is highly flexible in design and operation, adapting to the processing requirements of various materials. For example, during the production process, users can flexibly adjust parameters such as screw speed, temperature, and pressure to meet the processing needs of different materials. This high adaptability makes twin-screw extruders perform exceptionally well in the production of various chemical products, further improving production efficiency.

4. Practical Application Cases

Taking a chemical company as an example, this company produces engineering plastics with specific performance requirements. By adopting a high-speed twin-screw extrusion system, the company improved product quality while increasing production efficiency by 40%. Especially during the new product development phase, the twin-screw extruder provided more precise control, shortening the product development cycle by 30%. In addition, the high efficiency and low energy consumption of the equipment also saved the company significant production costs.

As an efficient and flexible chemical production equipment, the high-speed twin-screw extrusion system not only plays a key role in improving product quality but also increases production efficiency and reduces costs. By optimizing equipment parameters and improving production processes, companies can gain a competitive advantage in the fierce market competition. Therefore, chemical companies should actively introduce high-speed twin-screw extrusion technology, continuously optimize production processes, improve product quality, and reduce production costs to meet the increasingly complex market demands of the future.