With the continuous advancement of food processing technology, balancing production efficiency, food quality, and processing costs has become particularly important. In this process, the twin-screw extruder production line, as an advanced processing equipment, is widely used in the food production field due to its excellent mixing, shaping, and extrusion capabilities, especially in the areas of puffed foods, ready-to-eat foods, feed, and fortified foods.

So, what specific roles does a twin-screw extruder production line play in food processing?

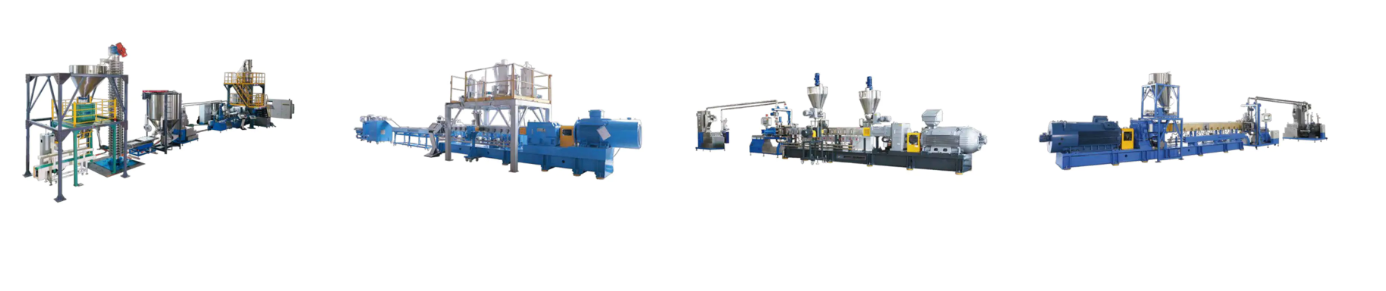

1. Introduction to Twin-Screw Extruder Production Lines

A twin-screw extruder is a machine that uses two opposing rotating screws to mesh and process raw materials into various shapes under high temperature and high pressure. Its main functions include mixing, heating, shearing, extruding, and shaping raw materials. Compared to single-screw extruders, twin-screw extruders offer superior mixing uniformity, better processing capacity, and higher production efficiency, making them widely used in plastics, chemicals, and food industries.

2. Main Roles of Twin-Screw Extruder Production Lines in Food Processing

(1) Production of Extruded Foods

Extruded foods, such as puffed rice, puffed corn, and puffed feed, are produced by rapidly puffing raw materials under high temperature and pressure conditions. Twin-screw extruders can precisely control the temperature and pressure during the extrusion process, ensuring that the raw materials are fully puffed, resulting in crisp, flavorful extruded foods.

During the puffing process, the two screws of the twin-screw extruder, through different spiral designs and relative rotational motion, achieve efficient material transfer and shearing, ensuring uniform mixing of the raw materials, resulting in a more stable puffing effect and reducing material waste during production. Simultaneously, the heat from the twin-screw extruder is evenly distributed during the puffing process, preventing localized overheating or undercooling from affecting the puffing effect.

(2) Ready-to-Eat Food Processing

Twin-screw extruder production lines are commonly used in the production of ready-to-eat foods, such as instant noodles, instant rice, and instant soup mixes. These foods require complex processing in a short time while maintaining good taste and nutritional content.

In the production of ready-to-eat foods, twin-screw extruders, through high-temperature heating and pressure, can quickly cook and gelatinize raw materials, giving noodles, rice, and other products good taste and easy-to-dissolve properties. At the same time, twin-screw extruders can also fully retain the nutrients in the raw materials during processing, reducing nutrient loss and improving the nutritional value of ready-to-eat foods.

(3) High-Protein Nutritional Foods

In recent years, with the popularization of healthy eating concepts, high-protein, low-fat, and fortified foods have become a popular market trend. Twin-screw extruders play a crucial role in the production of such foods, especially in the processing of plant proteins, animal proteins, and other functional ingredients.

Twin-screw extruders can process plant proteins (such as soy protein and pea protein) under high temperature and pressure, transforming them into more easily digestible and absorbable forms through appropriate physical and chemical reactions while retaining their nutritional value. Through precise control of the twin screw, different types of proteins can be mixed into a uniform structure, thereby improving the taste, nutrition, and functionality of the final product.

(4) Vegetarian Foods and Meat Alternatives

With the rise of vegetarianism and environmental awareness, meat alternatives (such as plant-based meat and vegetarian burgers) are gradually entering the market. Twin-screw extruders are widely used in this field to produce plant-based foods that mimic the texture of meat.

Through the efficient mixing, heating, and high shearing action of the twin-screw extruder, raw materials such as plant proteins, starches, and oils can be processed into meat substitutes, mimicking the texture and taste of meat. In this process, the twin-screw extruder can control the hydration, structure, and texture of the materials, ensuring that the final texture and taste of the product are close to that of meat.

(5) Pet Food Processing

Twin-screw extruders are widely used in the pet food industry, especially in the production of dry pet foods (such as pet biscuits and pet food). Through a twin-screw extruder, raw materials (such as meat, plant protein, and grains) can be efficiently mixed, expanded, and extruded to produce pet foods with high nutritional value and easy digestibility.

Twin-screw extruders can precisely control factors such as temperature, pressure, and humidity during the production process, thereby optimizing the nutritional components of pet food and improving its taste and digestibility. In addition, twin-screw extruders can improve the shelf life of pet food, prevent the loss of nutrients, and extend the product's shelf life.

3. Advantages of Twin-Screw Extruder Production Lines

High-Efficiency Mixing and Processing Capacity

The two screws of a twin-screw extruder mesh efficiently, mixing raw materials with different properties to ensure uniformity and stability, thereby improving production efficiency.

Flexible Processing Control

Twin-screw extruders can precisely control temperature, pressure, and shear rate, providing highly flexible adjustment for different types of food processing and adapting to various complex production needs.

Energy and Raw Material Savings

Through efficient heat transfer and material handling, twin-screw extruders maximize the utilization of raw materials, reducing energy consumption and lowering production costs.

High-Quality Food Processing

Twin-screw extruders can optimize the taste and appearance of food raw materials while preserving their nutritional components, giving products better market competitiveness.

As a core piece of equipment in food processing, twin-screw extruder production lines play a vital role in improving production efficiency, ensuring food quality, and meeting diverse market demands. Whether it's puffed foods, ready-to-eat foods, fortified foods, plant-based meat, or pet food, twin-screw extruders provide efficient and precise processing solutions.