How does the screw extruder pelletizing system control the diameter and shape of the pellets?

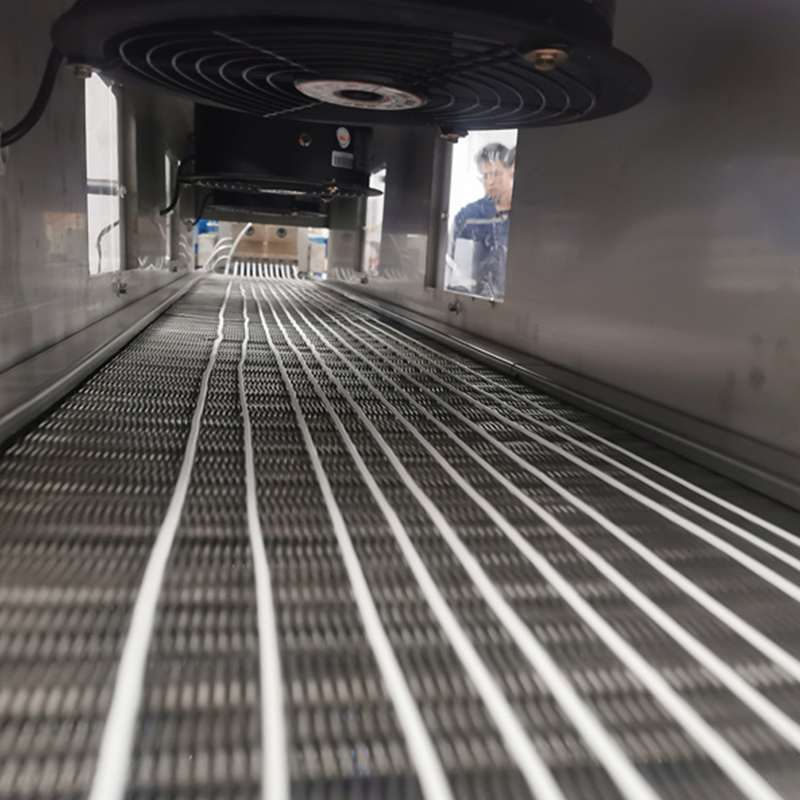

The diameter of the pellets is mainly determined by the aperture of the die plate installed at the end of the extruder. The die plate is provided with a series of evenly distributed holes through which the material is extruded and cut into pellets. Therefore, by adjusting the diameter of the holes on the die plate, the diameter of the pellets can be directly controlled. Increasing the screw speed or increasing the feed rate will increase the extrusion speed of the material when the die plate aperture remains unchanged, which may cause the pellets to be stretched before cutting, thereby increasing the pellet length, while the diameter may remain unchanged or slightly decrease. Therefore, the extrusion speed needs to be adjusted according to the target pellet size. The pellets can be cut by water-cooled knife cutting, hot knife cutting or rotary knife cutting. The position, speed and pressure of the cutting device need to be precisely controlled to ensure that the pellets are cut at the appropriate position to obtain a uniform pellet diameter.

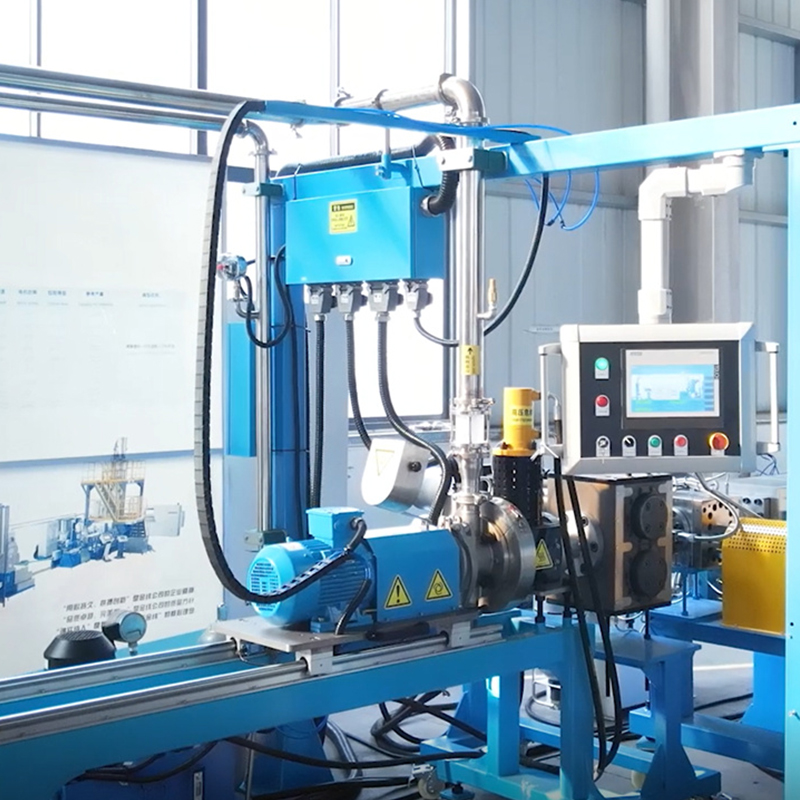

The geometry and configuration of the screw have an important influence on the mixing, plasticizing and extrusion processes of the material. By changing the screw thread shape, pitch, combination of screw elements, etc., the flow pattern and extrusion pressure of the material can be adjusted, thereby affecting the shape of the pellets. For example, using screw elements with stronger mixing capabilities can improve the uniformity of the material and help form a more regular particle shape. Although the die plate mainly controls the diameter of the particles, its shape may also have some effect on the final shape of the particles. For example, using a special shape of the hole may produce non-round particles. This effect is usually small and needs to be coordinated with other factors.

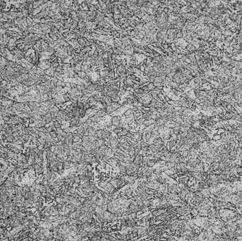

The physical and chemical characteristics of the material can also affect the shape of the particles. For example, high-viscosity materials may be more likely to form elongated particle shapes during extrusion, while low-viscosity materials may form shorter particles. Therefore, when selecting a screw extruder pelletizing system, it is necessary to consider the characteristics of the material and adjust the equipment and process parameters accordingly. Viscosity is a measure of the material's resistance to flow and directly affects the material's flow behavior in the screw extruder and its shape after extrusion. High-viscosity materials require greater shear and pressure to flow during extrusion, which may cause the material to be stretched at the extrusion orifice to form elongated particles. In contrast, low-viscosity materials are more likely to be extruded in a shorter shape.

In addition to the physical and chemical properties of the material, other process parameters such as screw speed, feed rate, barrel temperature distribution, extrusion pressure, etc. also have an important influence on the shape of the particles. These parameters need to be coordinated with each other to form the best combination to ensure that the material is fully plasticized and mixed during the extrusion process while avoiding excessive stretching or shear deformation.

The screw extruder granulation system controls the diameter and shape of the particles through template design, extrusion speed control, cut-off mechanism adjustment, and optimization of screw and process parameters. In practical applications, flexible adjustment and optimization are required according to specific materials and production needs.